No content results match your keyword.

Content

You have successfully logged out.

Not registered yet?

No content results match your keyword.

Content

No product results match your keyword.

Products

Sustainability stories

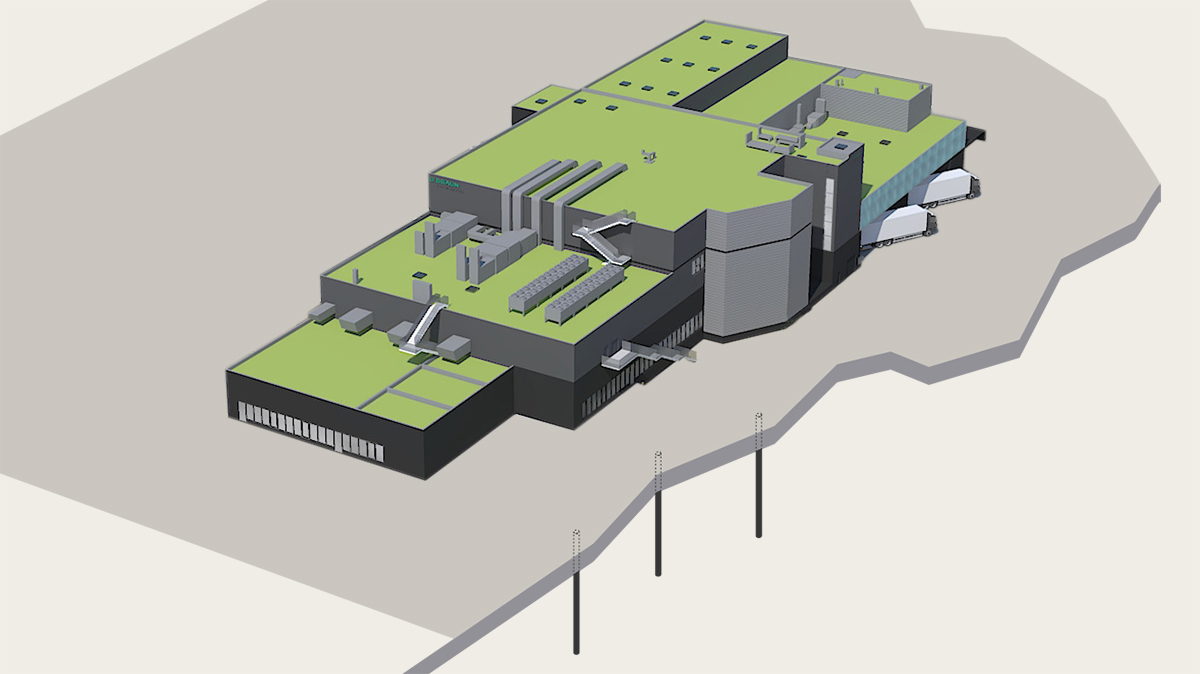

In Sempach, Switzerland, B. Braun is building a new production facility for disinfectant products. The plant is a flagship project in terms of sustainability. All of the heating used for our buildings and production is generated CO2 neutrally.

"As a family business, we have always have had future generations in mind. For decades, B. Braun has distinguished itself with its intelligent and economical use of resources. With our sustainability approach, we intend to continue setting ourselves ambitious goals in this area - always with an eye on protecting and improving the health of people around the world." This was stated by Dr. Melanie Pooch, Vice President of Corporate Strategy and Strategic Project, who is responsible for sustainability management at B. Braun. A key element of this is to plan all new B. Braun production buildings to be largely CO2-neutral in the future. At this point, the earth under Sempach comes into play.

“B. Braun values sustainability, innovation, and efficiency as a family business committed to future generations. With a focus on responsible climate protection, we aim to reduce CO2 emissions by 50% by 2030 while continuing to prioritise the health of people worldwide through resource-conscious practices.”

The secret lies in heat pumps. This system allows even small temperature differences - such as those between zero and 3.5 degrees - to be accumulated and exploited. One device alone would not get you very far, the special feature of N.I.C.O. is that a highly complex heat circulation system is installed in the plant. “There are three large tanks where we can store 90,000 gallons of water each at 90, 50, and 14 degrees. In addition, there is a huge latent or ice storage tank that can hold up to 300,000 litres of ice,” explains De Mesquita.

The last point requires special explanation. How can energy be stored in ice? Again, the answer is in the temperature difference. During the phase change from ice to liquid water, a lot of energy is released that can be harnessed using heat pumps.

A highly efficient circulation system: cold water is pumped into deep layers of the earth, heated to a high temperature, and then cooled and returned to the earth’s interior after the heat has been utilised.

/

31 probes embedded in the earth tap the heat stored in the ground at a depth of 200 metres and transport it to the surface via heat pumps for further use.

/

Three large water tanks with a total capacity of 270,000 litres store the water heated by geothermal energy, cooling and waste water.

/

The 300,000 litre ice storage tank stores heat in cold water. This energy is generated during the phase transition of water from the solid to the liquid state of aggregation.

/

The smart use of heat is just one of the benefits of redesigning a production facility. Another is that the actual production can be laid out in a particularly ergonomic way. “For one thing, we were now able to make production completely linear,” explains André Schaller. “Raw materials arrive at one end of the factory, are then processed, and finished products leave the building at the other end.” And, in N.I.C.O., the flow of materials and the flow of people will be separate. “Individual employees only have access to the production steps in which they are directly involved. This increases both the safety in production, and for the employees,” says Schaller.

“With N.I.C.O., we are showing that B. Braun is taking responsibility for climate protection. With the energy generation concept using the heat pump, we will save around 100,000 litres of heating oil per year at the Sempach production site alone.”